System Values - Stock - Warehousing

- WARNING: Changing these settings may cause unforeseen issues. If in doubt please check with KCSL's Support Team before making changes.

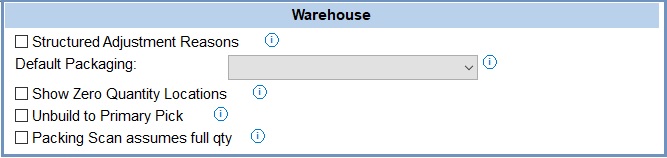

Warehouse

This area allows you to configure how certain warehouse aspects of Khaos Control behave.

- Structured Adjustment Reasons (default=unticked) :

: when adjusting stock the user will need to select a predefined reason from a drop-down before saving the adjustment. The adjustment reasons are set up in

: when adjusting stock the user will need to select a predefined reason from a drop-down before saving the adjustment. The adjustment reasons are set up in [ System Data | Stock | Adjustment Reasons ]. : the user can enter a Free Text Reason when adjusting stock in the

: the user can enter a Free Text Reason when adjusting stock in the [ Stock | Detail | Adjustments ]screen.

- Default packaging field (default=empty): default packaging is used by the Auto Pack option in the Packing stage of the Sales Invoice Manager and by Hand Held Terminals (HHTs). Before this option can be used, a stock item with the Level 1 and Level 2 Stock Type of Packaging must be created. in the

[ Stock | Detail | Options ]screen the option "Packaging Item" must be ticked. When the Auto Pack button in the Packing dialog is used, the system will use the packaging item defined here. However, if you want to associate a particular stock item with a packaging item then this can be done in[ System Data | Link Stock/Packaging ].

Notes- Only stock items with the 'Packaging Item'

ticked on their

ticked on their [ Stock | Detail | Options ]tab will appear in the Default Packaging drop-down field. - If a "Link Stock/Packaging" packaging item is defined against an item it will take precedence over the default packaging item.

- The packing stage may need enabling please go to Sales Invoice Manager - Edit Process Path for more information on enabling.

- When using Handheld Terminals (HHTs) this is the default packaging item if no other items have been defined for batch picking, see How To: Setup Packaging Options, therefore it must be configured.

- Only stock items with the 'Packaging Item'

- Show Zero Quantity Locations (default=unticked): This changes locations displayed in the GRN location lookup and in the Warehouse To grid of the Perform Location Movements dialog.

: the GRN lookup will also include empty locations linked to the item, and the Warehouse To grid will display ONLY empty locations where no stock item has been linked to them.

: the GRN lookup will also include empty locations linked to the item, and the Warehouse To grid will display ONLY empty locations where no stock item has been linked to them.  : the GRN lookup will only show locations where the item is linked and has a non-zero quantity, and the Warehouse To grid will show all locations in a warehouse.

: the GRN lookup will only show locations where the item is linked and has a non-zero quantity, and the Warehouse To grid will show all locations in a warehouse.

- Unbuild to Primary Pick (default=unticked):

: the system will assign the child items of builds to a primary pick (PP) location when the parent is unbuilt. If there is more than one PP location, the first location in the list will be used. If there are no PP locations, the ARRIVALS location will be used.

: the system will assign the child items of builds to a primary pick (PP) location when the parent is unbuilt. If there is more than one PP location, the first location in the list will be used. If there are no PP locations, the ARRIVALS location will be used. : the system will assign the child items of builds to the ARRIVALS location when the parent is unbuilt, see How To: Unbuild Stock Items using Warehouse Control.

: the system will assign the child items of builds to the ARRIVALS location when the parent is unbuilt, see How To: Unbuild Stock Items using Warehouse Control.

- Packing scan assumes full qty (default=unticked):

: When using the Pack Boxes dialog, the user can choose whether a single amount or the full amount is packed when a stock item is scanned, or a barcode is entered. The quantity scanned items in the packing dialog will pack the full item quantity when the qty field is blank or set to 0.

: When using the Pack Boxes dialog, the user can choose whether a single amount or the full amount is packed when a stock item is scanned, or a barcode is entered. The quantity scanned items in the packing dialog will pack the full item quantity when the qty field is blank or set to 0. : The quantity box will be set to 1 and this is the quantity of the item that will be moved to be packed. If set to 0 nothing will happen.

: The quantity box will be set to 1 and this is the quantity of the item that will be moved to be packed. If set to 0 nothing will happen.

Note: new systems are normally supplied with (default) values shown.